| Name: | Fixed integrated type ultrasonic flow meter |

|---|---|

| Model: | TUF-2000F |

| Nominal diameter: | DN15~6000(mm) |

| Accuracy: | ±1% |

| Working temperature: | -40~160℃ |

| Signal output: | 4~20mA, OCT, relay |

| Power supply: | DC24V |

Items | Specifications | |

Main unit | Accuracy | Better than ±1% |

Repeatability | Better than 0.2% | |

Principle | Transit-time measuring principle | |

Measurement Period | 500ms | |

Display | LCD with backlight, display accumulated flow/heat, instantaneous flow/heat, velocity, time etc. | |

Output | Analogue output: 4-20mA or 0-20mA current output. Impedance 0~1kW. Accuracy 0.1%. | |

OCT output: Frequency signal (1~9999HZ) | ||

Relay output: over 20 source signal (no signal, reverse flow etc.) | ||

RS485 serial port | ||

Input | Three analogue input | |

Three-wire PT100 resistor input (optional) | ||

Other functions | Automatically record the totalizer data of the last 64 days / 64 months / 5 years; The power-on time and corresponding flow rate of the last 64 power on and off events. Allow manual or automatic flow loss compensation The instrument working status of the last 64 days | |

pipe | material | Steel, stainless steel, cast iron, cement pipe, copper, PVC, aluminum, FRP etc. Liner is allowed |

Size | 15-6000mm | |

Straight pipe section | In the upstream it must be beyond 10D, in the downstream it must be beyond 5D, in the upstream the length must be beyond 30D from the access of the pump. (D stands for pipe diameter) | |

Liquid | Types | Water, sea water, industrial sewage, acid & alkali liquid, alcohol, beer, all kinds of oils which can transmit ultrasonic single uniform liquid |

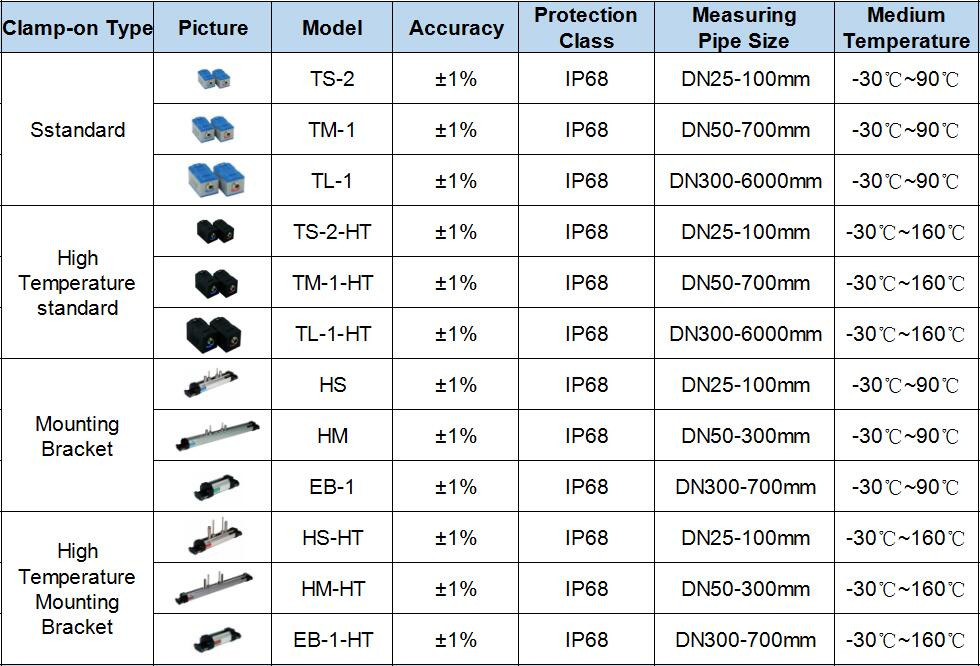

Temperature | Standard: -30˚C - 90˚C ,High-temperature:-30˚C - 160˚C | |

Turbidity | Less than 10000ppm, with a little bubble | |

Flow Direction | Bi-directional measuring, net flow/heat measuring | |

Environment | Temperature | Main Unit: -30˚C - 80˚C |

Transducer: -40℃ -110℃, Temperature transducer: select on enquiry | ||

Humidity | Main Unit: 85% RH | |

Transducer: water-immersible, water depth less than 3m | ||

Cable | Twisted Pair Line, standard length of 20m, can be extended to 500m (not recommended); Contact the manufacturer for longer cable requirement. RS-485 interface, transmission distance up to 1000m | |

Power Supply | DC24V | |

Power Consumption | Less than 1.5W | |

Protocols | MODBUS, M-BUS, Fuji extended protocol and other factory protocol | |

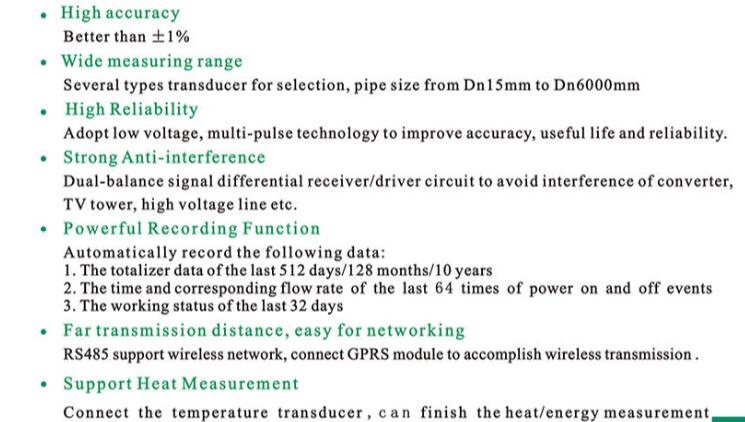

High Accuracy measuring

Accuracy: ±1%

Wide measuring range

Several types of transducers for selection, measuring pipe size from DN15mm to DN6000mm

Large capacity battery

Built-in rechargeable Ni-MH battery, provide over 12 hours of continuous operation

Built-in printer

Available to print data in real time, also available to timed print over 20 pre-set measuring results

Data storage

Store over 20 pre-set measuring results to SD card, make it easy to data analysis and statistics

Rs485 communication interface

Upload the parameters and measuring results to computer

Various input and output signal

Output signal: 4-20mA, pulse signal, relay signal Input signal: 3 way 4-20mA

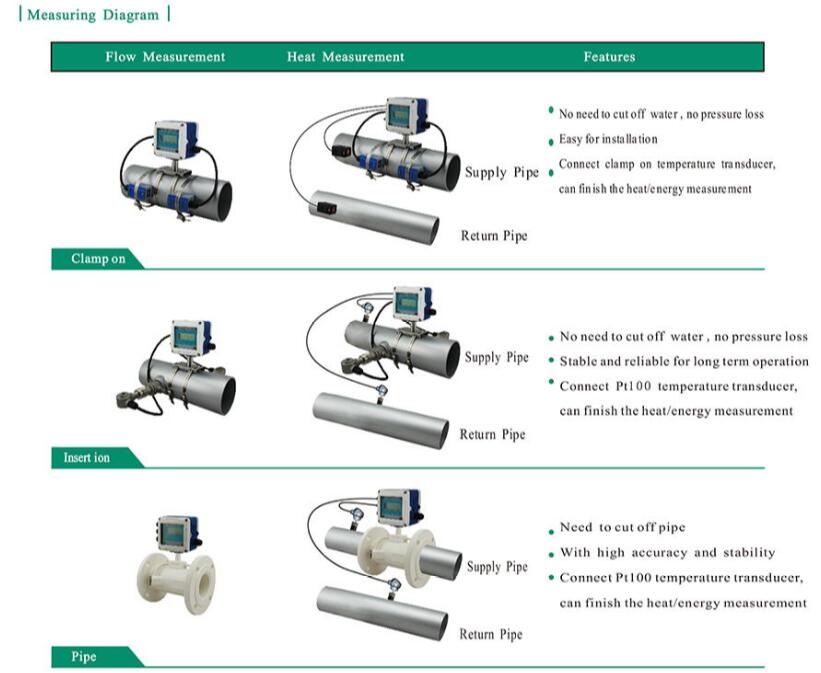

The TUF-2000F ultrasonic flow meter is designed to measure the fluid velocity of liquid within a closed conduit. The transducers are a non-contacting, clamp-on type, which will provide benefits of non-fouling operation and easy installation.

The TUF-2000F transit-time flow meter utilizes two transducers that function as both ultrasonic transmitters and receivers. The transducers are clamped on the outside of a closed pipe at a specific distance from each other. The transducers can be mounted in V-method where the sound transverses the pipe twice, or W-method where the sound transverses the pipe four times, or in Z-method where the transducers are mounted on opposite sides of the pipe and the sound crosses the pipe once. This selection of the mounting method depends on pipe and liquid characteristics. The flow meter operates by alternately transmitting and receiving a frequency modulated burst of sound energy between the two transducers and measuring the transit time that it takes for sound to travel between the two transducers.

The flow meter can be applied to a wide range of pipe flow measurements. Applicable liquids include pure liquids as well as liquid with small quantity of tiny particles.

Examples are:

★ Water (hot water, chilled water, city water, sea water, waste water, etc.);

★ Sewage with small particle content;

★ Oil (crude oil, lubricating oil, diesel oil, fuel oil, etc.);

★ Chemicals (alcohol, acids, etc.);

★ Plant effluent;

★ Beverage, liquid food;

★ Ultra-pure liquids;

★ Solvents and other liquids