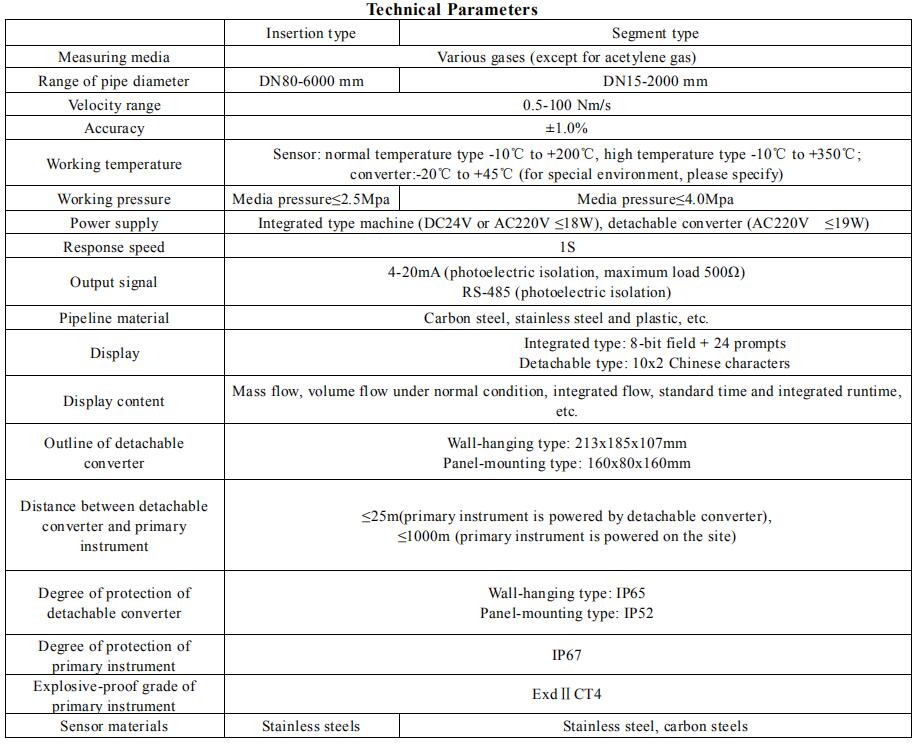

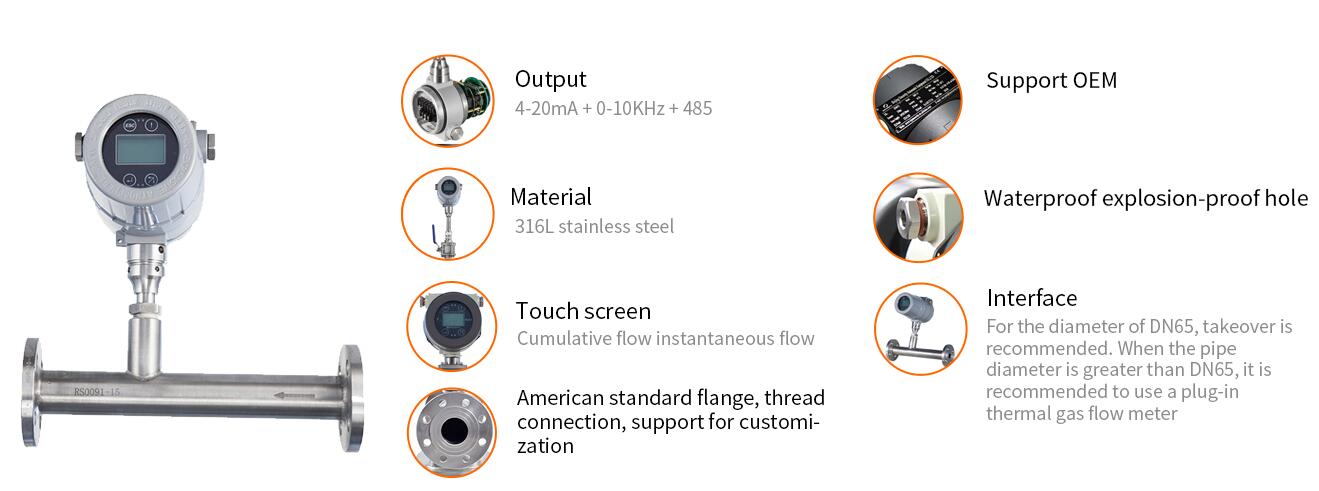

| Name: | Thermal gas mass flow meter |

|---|---|

| Measuring media: | Various gases (except for acetylene gas) |

| Process Connection: | DN15~2000 |

| Accuracy: | 土0.10% |

| Working temp: | -10~ 350℃ |

| Protection: | IP67 |

| Output: | 4-20mA, RS485 Modbus RTU,HART |

| Explosion proof: | Exd CT4 |

| Velocity range: | 0.5-100 Nm/s |

· Direct measurement of gas mass flow without any temperature or pressure compensation.

± 1.0% high accuracy, fast response time, and very wide flow range. Even at the lower limit of the flow range, the accuracy is still very good.

· Applications: industrial plants, oil and gas upstream and downstream production, water and wastewater treatment plants, etc.

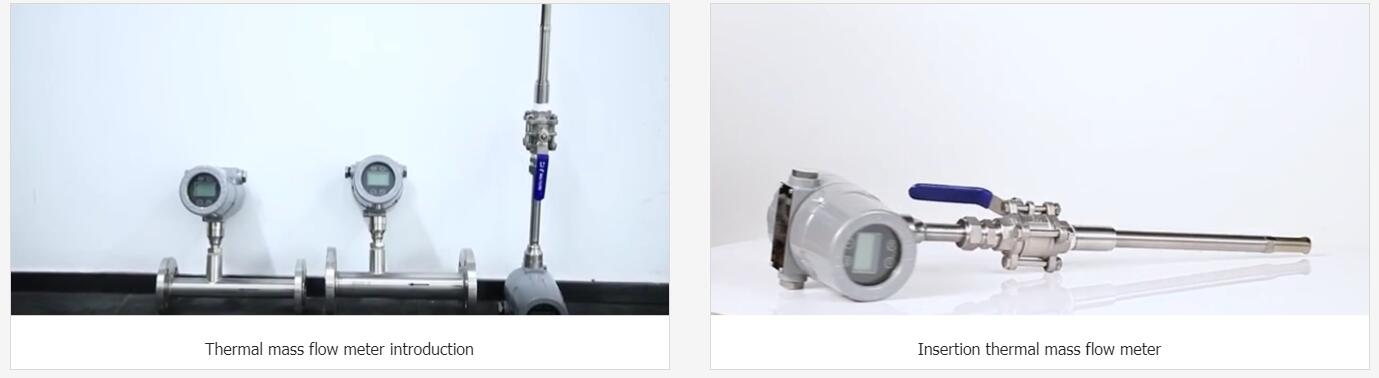

Thermal mass flowmeters are suitable for all industrial and test platform applications that require fast, accurate gas measurement. The flowmeter directly indicates the mass flow or standardized volume flow of the gas without any additional pressure and temperature compensation. They have impressive high accuracy, short response times and a very wide flow range, with almost no loss of accuracy even at the lowest flow.

Thermal mass flowmeters are suitable for all industrial and test rig applications that demand quick and precise gas measurement. The flowmeters directly indicate the mass flow or normalized volume flow of gases without any additional pressure and temperature compensation. They have an impressively high accuracy, short response time and a very wide flow range with virtually no loss of accuracy even at the lowest flow rates.

General

- Liquids with transient gas entrainment

- Cryogenic or high temperatures (-200…+400°C /-328…+752°F)

- Super critical gases

- Custody transfer (CT)

Chemical and other process industries

- Concentration and density measurement

- Bulk loading

- Batching and blending to reactors

- Hydrocarbon cracking

Oil and gas industry

- Metering skids, bulk loading, pipeline transfer

- "Bypass" density measurement

- Liquefied Natural Gas (LNG)

- Bulk loading

- In-line density measurement

- Multiphase measurement in upstream applications

Food and beverage industry

- Batching, dosing, filling

- Mass flow measurement of ice cream and milk (e.g. at the raw milk reception)

- Measurement of flow, density, specific gravity in brewing processes - Dosing of hop extract

- Measurement of Brix, density and flow in fruit juices

- Dosing of natural oils, grease, vegetables (e.g. spinach) etc.

- CO2 injection in soft drink production

Pharmaceutical industry

- Batching, dosing, filling

- Solvent extraction

Marine industry

- Bunkering and fuel consumption measurement

Pulp and paper industry

- Additives, bleaches and colourants

- Crystallising, solidifying and cryogenic products